Innotech Engineering offers a reliable range of Foam Testing Equipment designed to assess the physical and mechanical properties of foam materials used in furniture, bedding, automotive, packaging, and insulation industries. Our machines help manufacturers ensure that foam products meet performance, comfort, and safety standards before reaching the market.

✅ Key Testing Machines:

- Compression Set Tester

Measures the foam’s ability to return to its original thickness after prolonged compressive stress—crucial for seat cushions, mattresses, and soundproofing foam. - Indentation Hardness Tester (ILD Test)

Evaluates the firmness of flexible polyurethane foam by determining the force required to compress a sample to a specific percentage of its thickness. - Tensile and Tear Strength Tester

Determines the tensile strength and elongation properties of foam sheets and blocks, as well as resistance to tearing. - Resilience Tester (Ball Rebound Test)

Measures the elastic recovery and bounce-back property of foam, which indicates comfort and energy absorption. - Density Tester

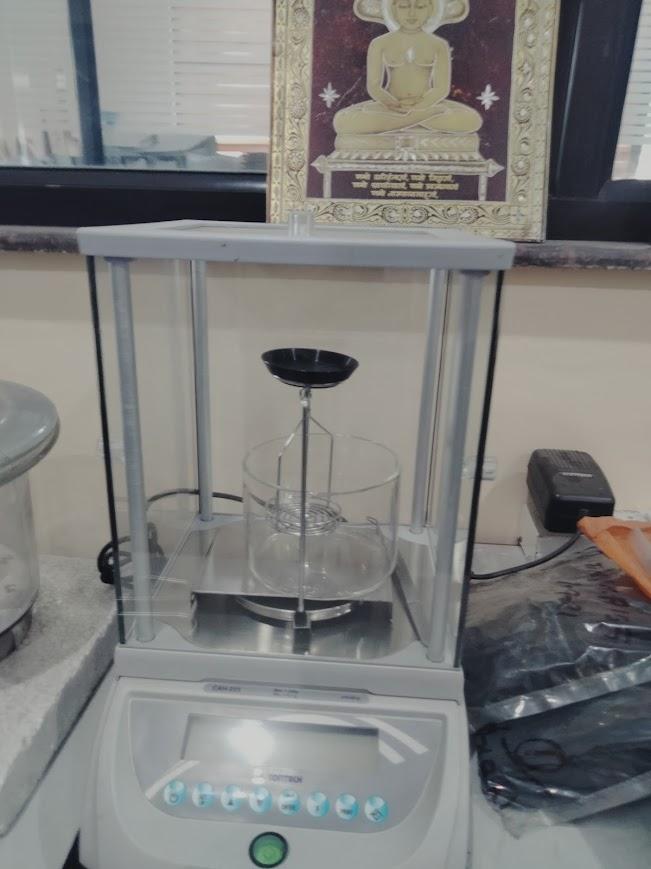

Calculates the foam’s mass per unit volume, a key factor in determining quality, softness, and durability. - Flammability Tester

Assesses the combustion resistance of foam under controlled ignition conditions—essential for safety and compliance.

🌟 Features:

- Accurate, repeatable test results with computerized controls

- Durable construction suitable for production and lab environments

- Custom fixtures for varying foam types and shapes

- Conforms to IS, ASTM, ISO, and EN standards

- Ideal for furniture manufacturers, automotive OEMs, R&D labs, and QC departments

Innotech’s foam testing solutions are engineered to help manufacturers guarantee product performance, safety, and customer satisfaction.